Rbsic Sisic Silicon Carbide Bricks Refractory Ceramic Panel Manufacturer

Basic Info

| Model NO. | RBSIC |

| Application | Structure Ceramic, Industrial Ceramic |

| Material | Silicon Carbide |

| Type | Ceramic Plates |

| Temperature of Application | 1380c |

| Density | 3.05 |

| Open Porosity | 0.1 |

| Bending Strength -a | 250 (20c) |

| Bending Strength -B | 280 (1200c ) |

| Modulus of Elasticity-at Gpa | 330(20c) |

| Modulus of Elasticity -B | 300 ( 1200c ) |

| Thermal Conductivity | 160;45 (1200c ) |

| Coefficient of Thermal Expansion | 4.5 |

| Rigidity | 13 |

| Acid-Proof Alkaline | 160;Excellent |

| Color | Black |

| Size | Customized Size |

| Steel | Sisic Lined Steel Pipe |

| Thickness | 6-25mm |

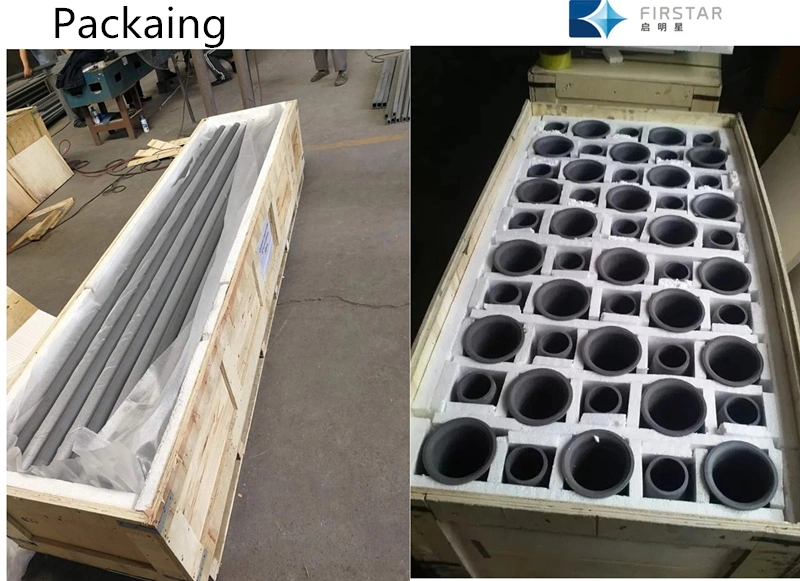

| Transport Package | Wood Carton |

| Trademark | firstar |

| Origin | China |

| HS Code | 6909120000 |

| Production Capacity | 1500PCS/Month |

Product Description

Rbsic Sisic Silicon Carbide Bricks Refractory Ceramic Panel ManufacturerSilicon carbide Tiles

Reaction bonded silicon carbide is a multi-phased material typically containing 7-15% silicon metal, some minor amount of unreacted carbon, with the remaining body being SiC. Reaction bonded SiC materials are manufactured utilizing a variety of processes depending on desired final product geometry, configuration, and required tolerances.

Reaction bonded silicon carbide has proven to be an excellent material choice for wear applications such as pipe liners, flow control chokes and larger wear components in the mining as well as other industries. CALSIC RB offers an economical and reliable material option for many applications where the corrosion resistance or wear resistance of CALSIC S (sintered silicon carbide) is not necessary.

Typical properties of silicon carbide are:

Excellent thermal shock resistance

Excellent hot strength

Excellent abrasion resistance

Good thermal conductivity

Relatively low coefficient of thermal expansion

Typical applications for silicon carbide are:

Kiln furniture for powder metal and ceramic processing

Kiln components including:

--hearths

--entrance tiles

--skid rails

--muffles

--side walls

--arches

Available Shape and sizes:

Thickness: from 6mm up to 25mm

Regular Shape: SiSiC tiles, SiSiC Pipe tiles, SiSiC Three Links, SiSiC Elbow, SiSiC Cone Cyclone.

Remark: Other sizes and shape are available upon requests.

Packaging:

In carton box, packed in fumigated wooden pallet with net weight 20-24MT/20′FCL.

FAQQ: What is your experience in your products?

A: We have 22 years experience in this industry line. We are professional manufacturer in this area.

Q: What is your MOQ?

A: The MOQ is different as per different products, for example, 1 Ton for ceramic ball.

Q: Can you accept small quantity sample order before production?

A: Yes, we can offer sample for your testing first

Q: Can you provide free sample?

A: Yes, within 1kg.

Q: What is your production time?

A: We have large stock for standard products. Normally within 7-10days after receipt the deposit.

Q: What are your payment terms?

A: T/T, L/C, Western Union